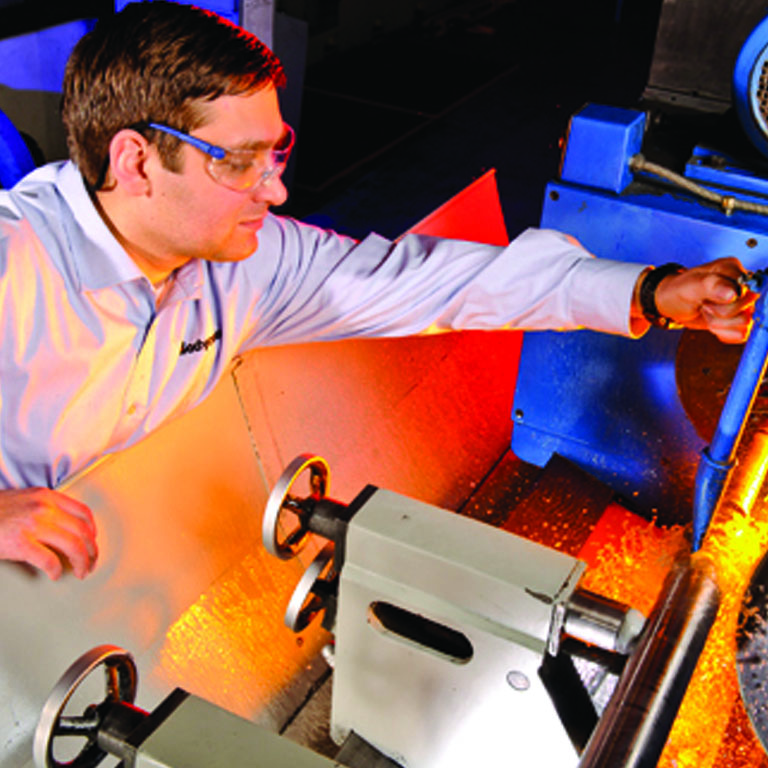

Specialised coatings are used to prolong the working life of components and protect them from environmental factors such as corrosion and abrasion. The range of coatings available includes thermally sprayed ceramic and metallic coatings and chemically formed ceramics. These covers a wide variety of applications, primarily in the aerospace, defence and energy markets.

Controlling the Flow

Gate valve

Gate valves and seats are used in the oil & gas industry to control the flow of oil-containing fluid extracted from the reserve. Within the well, pressures may be in excess of 15,000psi (or 6.5 tonnes per square inch) combined with high temperature. Such an extreme environment requires high performing components and reliable surface coating treatment. Bodycote applies a tungsten carbide coating to the valve and seat to provide a metal-to-metal seal that is highly wear and corrosion resistant.

The valve componentis machined from high grade stainless steelor nickel based alloy.

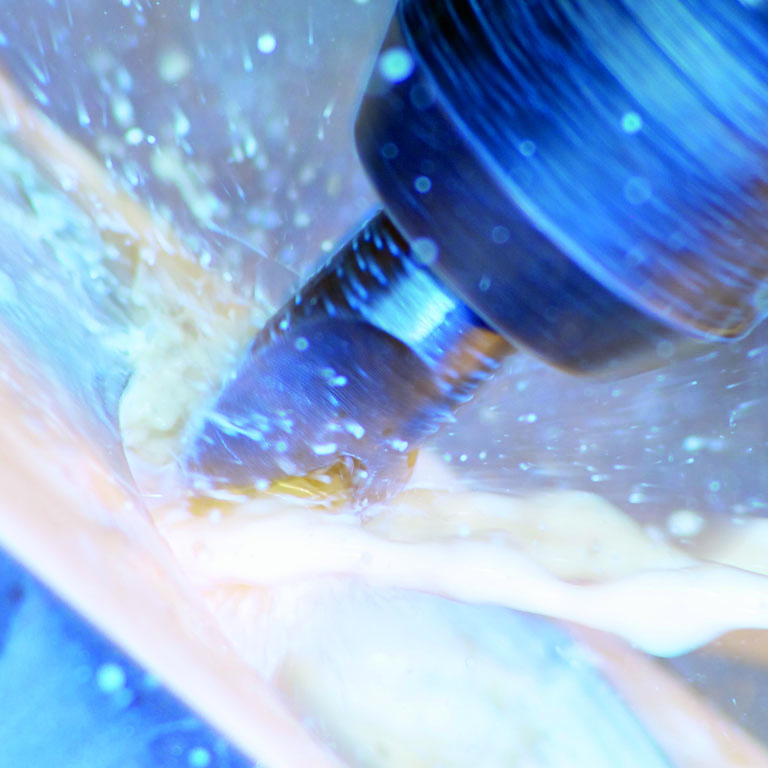

The valve component is coated with gas tight tungsten carbide to provide a wear and corrosion resistant surface.

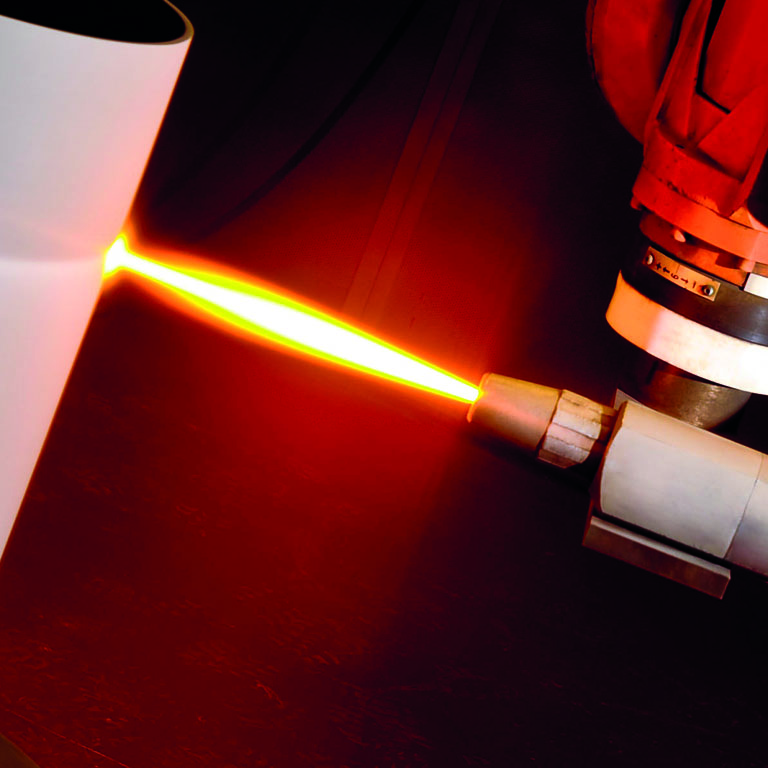

The coated surface is ground to specification to prepare it for polishing.

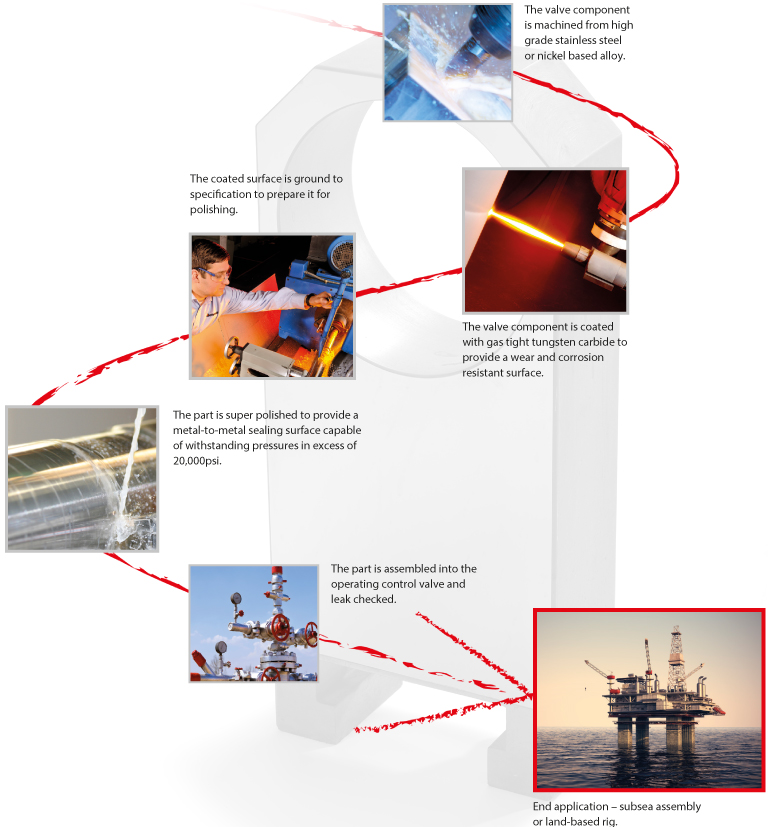

The part is super polished to provide a metal-to-metal sealing surface capable of withstanding pressures in excess of 20,000psi.

The part is assembled into the operating control valve and leak checked.

End application – subsea assemblyor land-based rig.