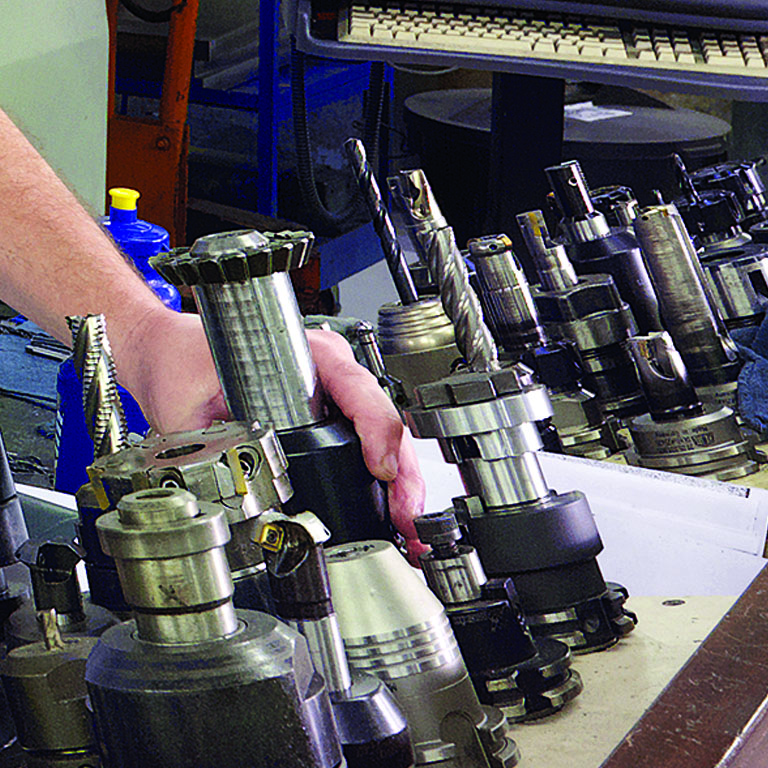

CiD® is a proprietary Bodycote thermochemical heat treatment for simultaneous improvement of corrosion resistance and wear properties through generating an iron nitride-oxide compound layer on steel. CiD® is favoured for components that are subjected to a corrosive environment in combination with wear.

Stress Ball

Ball studs

Used in virtually every automobile made, ball studs are located within the ball joints in a vehicle's steering system, between the wheels and suspension, allowing rotating movement – similar to the way a human hip joint works. Because of their function and position within the vehicle, they must be extremely strong, corrosion resistant and able to cope with weight and stress. Their effective operation is critical to the safety of the vehicle and, therefore, the driver. Bodycote's proprietary CiD® process ensures the parts achieve the necessary material properties.

The ball studs are cold forged from heat treatable steel.

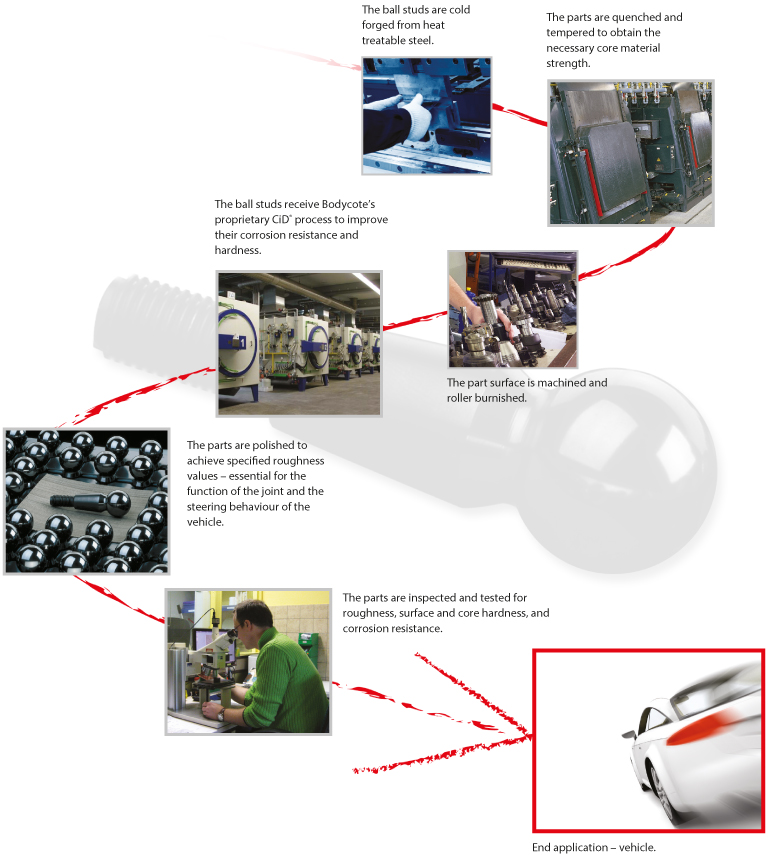

The parts are quenched and tempered to obtain the necessary core material strength.

The part surface is machined and roller burnished.

The ball studs receive Bodycote's proprietary CiD® process to improve their corrosion resistance and hardness.

The parts are polished to achieve specified roughness values – essential for the function of the joint and the steering behaviour of the vehicle.

The parts are inspected and tested for roughness, surface and core hardness, and corrosion resistance.

End application - vehicle