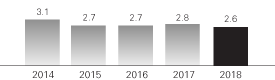

Total reportable case rate (TRC)1

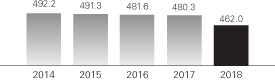

Carbon footprint2

(tonne CO2e/£m sales normalised3)

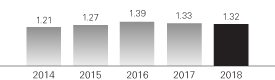

Water consumption

(thousand m3/£m sales normalised3)

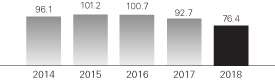

Chlorinated solvents

(kg/£m sales normalised3)

ISO 14001 accredited facilities

(%)

- Total reportable case rate is defined as the number of lost time accidents 5 200,000 hours (approximately 100 man years), divided by the total number of employee hours worked.

- CO2e is carbon dioxide equivalent, which represents the CO2 release due to our energy usage.

- Normalised statistics restate prior year figures using current year IEA carbon conversion factors and current year average exchange rates.

As a Group, Bodycote is committed to acting responsibly as a good corporate citizen, to reducing the environmental impact of the Group's activities and to providing our employees with a safe working environment.

Bodycote's stakeholder model shows how its interactions on various levels contribute towards socioeconomic growth and development. These exchanges, based on mutually beneficial relationships, provide the basis for the Group's growth and sustainability, which in return provides benefits to employees, investors, customers and society communities.

Our approach

Bodycote's objective is to create superior shareholder returns through the provision of selected thermal processing services that are highly valued by our customers. We aim to achieve this in a safe working environment, while continually seeking to minimise the impact on the environment.

Bodycote is dedicated to improving the management of corporate responsibility issues and is implementing policies and initiatives to achieve this goal. The future success and growth of the Group is intrinsically linked to our ability to ensure the Group's operations are sustainable and that we can nurture and develop our talent.

Our people

The strength of the Group primarily rests in its people and one of the key challenges for management is to ensure availability of appropriately qualified people to support its continued growth. Bodycote is fortunate to have a competent and committed international team that is well respected in technical and business circles.

Bodycote invests in the training and development of its people both at local and Group level. The Group is committed to providing the appropriate skills and training which will allow its employees to operate effectively and safely in their roles and deliver results.

A tool to develop further understanding and skill in the area of performance management is in place and is being used globally through the management population. Through communication of clear messages coupled with skills development, the organisation aims to raise the capability of its management population in driving performance. This initiative is backed by a performance management system which supports the process.

Bodycote's employment policies are non-discriminatory, complying with all current legislation to engender equal opportunity irrespective of age, race, gender, ethnic origin, nationality, religion, health, disability, marital status, sexual preference, political or philosophical opinions or trade union membership. Harassment is not tolerated.

Female representation on our Board during 2018 was 43% (2017: 17%) and at manager level it is 26% (2017: 26%). Females represent 19% (2017: 19%) of our total workforce.

| Male | Female | Total | Male | Female | Total |

| Directors | 4 | 3 | 7 | 57% | 43% | 100% |

| Managers | 52 | 18 | 70 | 74% | 26% | 100% |

| Other staff | 4,539 | 1,030 | 5,569 | 82% | 18% | 100% |

| 4,595 | 1,051 | 5,647 | 81% | 19% | 100% |

Culture and Values

It is not just important what we do but how we do it and how we behave in our Company. How we operate as a Group and the behaviours that we expect from all our employees are expressed in our Core Values. Our values represent Bodycote and its people and our commitment to the Company and the business.

Our Core Values are straightforward and are as follows:

Honesty and Transparency

We are honest and act with integrity. Trust stems from honesty and trust is at the heart of everything we engage in: our customers trust us to deliver what we say we will, our colleagues trust us to act in their best interests and our suppliers trust us to conduct business according to agreed terms. This is not something we take for granted. Bodycote lives by a culture of honest and transparent behaviour, which is at the core of all our business relationships.

Respect and Responsibility

We manage our business with respect, applying an ethical approach to our dealings with those we interact with. We respect our colleagues, who are all of the employees of Bodycote. Part of our respect for our colleagues is our commitment to safe and responsible behaviour and our fundamental belief that no one should come to any harm at work. We show respect for our customers, our suppliers and our competitors. We respect the communities around us and behave as responsible corporate citizens by being compliant with the laws and regulations of the countries in which we do business and by ensuring that our effect on the environment is minimal. We believe in taking ownership for, and being mindful of the impact of, our actions.

Creating Value

Creating value is the very essence of our business and needs to be the focus of our endeavours. We create value for our customers, our employees and our shareholders. The realities are harsh. If we do not create value for our customers then we have no reason for existence. If we do not create value for our employees there will be no one to create value for our customers. Our shareholders rightfully require that we ultimately create value for them as they are the owners of the business.

Human rights

Bodycote's human rights policy is consistent with the Universal Declaration of Human Rights and the UN Global Compact's ten principles.

We prohibit forced, compulsory and underage labour and any form of discrimination based on age, race, gender, ethnic origin, nationality, religion, health, disability, marital status, sexual preference, political or philosophical opinions or trade union membership. Appropriate mechanisms are in place to minimise the potential for any contravention of these rules.

By publicly posting our human rights policy on www.bodycote.com, stakeholders worldwide can alert us to potential breaches of the policy. Our internal systems also support compliance with our policy and we have a robust Open Door Line for employees to report alleged violations of law and/or our policies on a confidential basis and in their own language. In the jurisdictions in which we employa majority of our employees, there are laws applicable to many of the areas dealt with in our human rights policy.

The Modern Slavery Act

Bodycote plc has conducted a risk assessment on our supply chain using the UK Government's published guidance entitled 'Transparency in Supply Chains'. Suppliers in those countries identified in Walk Free Foundation's 2016 Global Slavery Index as being the most vulnerable to human rights issues in the supply chain have been identified for further review and audit.

We have a Code of Conduct which sets out our policy on compliance with legislation, child labour, anti-slavery and human trafficking, and conditions of employment, health and safety and the environment.

The Anti-Slavery and Human Trafficking statement was reviewed by our Board of directors in June 2018 and was published on our website. The statement will be reviewed on an annual basis.

Customers and suppliers

Bodycote has no significant suppliers who are wholly dependent upon the Group's business and has no significant suppliers on which the Group is dependent upon for a substantial part of its business. Suppliers are paid in line with contractual and legal obligations.

We endeavour to respond quickly to changing customer demand, to identify emerging needs and to improve service availability and quality. We stay close to our current and potential customers, building long-term relationships.

Community

Bodycote seeks to play a positive role in the local communities in which it operates by providing employment opportunities, and building goodwill and a reputation as a good neighbour and employer.

Responsible business ethics

The Group has a robust governance structure in place to support business ethics and a series of policies which details its commitments and standards in this area. We recognise that rules alone are not sufficient to ensure wrongdoing is avoided – a combination of rules and values is needed to help embed a healthy business culture. The Group's approach is to set the tone of an ethical business culture from the top, demonstrating commitment to the right values and behaviours of all employees.

All Bodycote personnel are expected to apply a high ethical standard, consistent with an international UK-listed company. Directors and employees are expected to ensure that their personal interests do not at any time conflict with those of Bodycote. Shareholder employees are advised of, and comply with, the share dealing code.

Bodycote has systems in place that are designed to ensure compliance with all applicable laws and regulations, and conformity with all relevant codes of business practice. Furthermore, Bodycote does not make political donations.

With regard to competition, Bodycote aims to win business in a differentiated high-value manner. The Group does not employ unfair trading methods and it competes vigorously but fairly within the requirements of applicable laws. Employees are prohibited from either giving or receiving any inducements.

Our Open Door Policy has been translated into all languages used throughout the Group. The policy allows employees to report their concern confidentially, verbally or in writing, to an independent third party provider, ensuring anonymity.

Responding when wrongdoing is reported

When incidents are reported, whether through internal or external mechanisms, they are passed to the Group Head of Risk for investigation and determination of the appropiate steps to be taken for the matter to be addressed.

Supporting employees who speak up

When our employees do the right thing by speaking up against instances of wrongdoing, we believe it is crucial that the Group also does the right thing and ensures that there are no repercussions for their actions.

Online training courses in respect of Anti-Bribery and Competition Law have been designed and translated into the major languages used throughout the Group. All relevant employees have completed the interactive courses.

Operational SHE performance

Bodycote is committed to continual improvement in our safety, health and environmental performance (SHE). We are committed to complying with all local legislative requirements as a minimum and establishing consistent and robust best practices at all of our sites to deliver consistently high performance across all aspects of SHE management.

Safety and health

The nature of the Group's operations is such that employees are inevitably exposed to hazards in the workplace. Bodycote aims to manage these hazards and thereby minimise risks to employees through the deployment of robust safety control systems and procedures, and seeks to establish these at all sites.

Total Recordable Case rate (TRC)

Bodycote uses a global incident reporting and SHE management tool at every operational site enabling more consistent and thorough reporting of workplace injuries, near misses and unsafe conditions. In 2018, the TRC rate was 1.7.

In 2018 the number of 'Opportunities for Improvement' (OFIs) reported by employees increased by 41.7% across the Group. This improvement demonstrates stronger engagement of employees in proactively raising and rectifying safety issues. Accidents, though regrettable and unacceptable, represent learning opportunities, and is the reason that accurate reporting is an essential part of building a robust safety management system.

As our database continues to develop we are able to analyse and prioritise our safety action programmes more effectively. The most frequent cause of recordable cases is related to manual handling of parts and lifting operations and has a number of underlying causes. This is currently the subject of a Group-wide review and will be a focus for risk reduction activities over the next few years.

In 2018 additional Group SHE capital investment was made in pedestrian safety and ergonomics/manual handling improvements to reduce accident frequency, and address the severity of risk in these areas.

Reportable cases and lost time injuries are reviewed during executive management meetings and Board meetings. In addition, the executive management team reviews incidents which did not result in injury but were considered to have been serious or to have had a high potential impact. All serious incidents and high potential incidents are also reviewed by the Group SHE Committee and are cascaded within the business as appropriate to ensure that preventive actions are taken.

Environment

A proactive approach to improving energy efficiency means that Bodycote has implemented a variety of systems to reduce water and gas consumption, and to reuse heat energy. In order to lessen the impact on the environment Bodycote continues to seek ISO 14001 accreditation at all of our operational facilities.

At every stage where Bodycote is involved in the manufacturing cycle, our operational aim is to reduce the overall impact on the environment, not just in our own operations, but also those of our customers. Bodycote operates modern, efficient equipment, which is operated around the clock so as to optimise treatment processing cycles. Without Bodycote, many companies would be using older in-house technology and running their equipment at reduced capacity, both of which drain energy resources. Working with Bodycote enables our customers to commit more easily to carbon reduction initiatives.

Bodycote also reduces the carbon footprint of our customers' activities by increasing the lifespan of their products, by improving metallurgical properties and by enhancing corrosion resistance. For example, surface treatment technology is widely used in the reclamation of damaged and worn components, offering a cost-effective and energy-efficient alternative to the need to manufacture new replacement parts. The treated parts often last up to twenty times longer than the original.

While thermal processing is an energy-intensive business, it is a vital part of the manufacturing supply chain and its use saves the energy it consumes many times over. Moreover, by effectively consolidating the heat treatment requirements of our many thousands of customers, Bodycote significantly reduces the overall required energy consumed compared with the energy that would be consumed if each customer treated their own products. In this regard, Bodycote should be viewed as an enabler to the goal of a reduction in emissions.

Greenhouse gas emissions

| 2018 | 2017 | 2017 (normalised) |

|---|

| CO2e emissions (ktCO2e) | Intensity ratio (tCO2e/£m) | CO2e emissions (ktCO2e) | Intensity ratio (tCO2e/£m) | CO2e emissions (ktCO2e) | Intensity ratio (tCO2e/£m) |

|---|

| Scope 1 | 150.6 | 204.7 | 150.3 | 217.9 | 149.9 | 217.1 |

| Scope 2 | 189.3 | 257.3 | 189.8 | 275.2 | 181.7 | 263.1 |

| Statutory total | 339.9 | 462.0 | 340.1 | 493.1 | 331.7 | 480.3 |

Scope 1 emissions are direct emissions resulting from fuel usage and the operation of facilities. Scope 2 emissions are indirect energy emissions resulting from purchased electricity, heat, steam or cooling for own use.

The financial control consolidation approach has been used to report the above data. This method aligns with the reporting scope in the financial statements. The Group collects electricity and natural gas usage information from each facility on a monthly basis. The Group then applies the International Energy Agency (IEA) published national carbon conversion factors to calculate the total tonnage of CO2e produced.

All entities and facilities under financial control are included within the disclosure. Emissions less than 1% of the Group's total CO2e relating to fugitive emissions and owned vehicles are not significant and are excluded. As such there are no significant omissions from this disclosure.

Total Energy Consumption

| 2018 |

|---|

Group Energy consumption

kWh | UK Energy consumption

kWh | Proportion of energy consumed in the UK |

|---|

| Total Energy Consumption kWh | 1,410,246,385 | 78,855,906 | 5.6% |

In 2018 the aggregate of the annual quantity of energy from activities for which the Company is responsible worldwide and the annual quantity of energy consumed resulting from the purchase of electricity, heat, steam or cooling by the Company for its own use was 1,410,246,385 kWh; the proportion of that figure that relates to energy consumed in the UK is 5.6%.

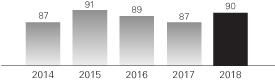

ISO 14001 accredited facilities

Reducing the environmental impact of the Group's activities is taken very seriously. Compliance with the requirements of ISO 14001 helps to minimise the risk of adverse environmental effects at Bodycote's sites. At the end of 2018, 90% of our operating facilities had achieved ISO 14001 accreditation (2017: 87%). Operational plants which have not yet received accreditation to the standard are working towards it.

Carbon footprint and water consumption

The absolute energy usage decreased by 0.03% and per £m sales (at constant exchange rates) decreased by 3.8%.

The total CO2e emissions per £m sales in 2018 were 466.6 Te (2017: as previously reported 493.1 Te; normalised† 480.3 Te).

The Group's total CO2e emission data is based on Scope 1 and Scope 2 emissions, as defined by the UK Government's DEFRA, and data relating to this has been calculated to include country-specific electricity conversion factors. In previous years this has been supplied by DEFRA directly. However, as of January 2017 DEFRA no longer supplies these conversion factors for non-UK companies. This has now been sourced by the Group directly from the International Energy Agency (IEA). There are some significant differences in these conversion factors. As a result all previous years have now been restated using IEA conversion factors to ensure that year-on-year comparisons are consistent.

On a normalised† basis, water usage per £m sales decreased by 0.8%. On a non-normalised basis, water usage per £m showed no change.

In 2015 our EU based operational sites reviewed their operations to ensure compliance with the Energy Efficiency Directive 2012/27/EU. This Directive is transposed into local legislation and requires sites to monitor their energy usage and assess energy reduction opportunities which are in addition to the ongoing energy saving activities at sites. One mechanism for ensuring compliance is for sites to become certified to ISO 50001 Energy Management Systems Standard. This enables sites to measure energy usage consistently and target the most effective ways of reducing energy usage. Our sites in Germany, Austria, Denmark, the Netherlands and the UK are largely already certified and working on further energy management programmes.

Bodycote uses established systems to develop best practice at specific sites and across the wider Group.

The continued replacement of traditional lighting with LED for environmental and improved safety has resulted in further CO2 reductions.

Bodycote submits data on CO2 usage to the Carbon Disclosure Project, one of the leading carbon reporting and verification bodies. The Company is now standing at a 'C'.

Chlorinated solvent use

The use of chlorinated solvents in Bodycote's thermal processing activities has been reduced in recent years as aqueous degreasing facilities have been introduced. In 2018, the normalised† solvent use showed a further decrease of 17.5% compared with the previous year.

Cautionary statement

The Strategic report has been prepared solely to provide information to shareholders to assess how the directors have performed their duty to promote the success of the Group.

The Strategic report contains certain forward-looking statements. These statements are made by the directors in good faith based on the information available to them up to the time of their approval of this report and such statements should be treated with caution due to the inherent uncertainties, including both economic and business risk factors, underlying any such forward-looking information.

Approval

The Group Strategic report of Bodycote plc was approved by the Board of directors and signed on its behalf by:

S.C. Harris

Group Chief Executive

8 March 2019

* Statutory carbon reporting disclosures required by Companies Act 2006.

† Normalised statistics restate prior year emissions using current year IEA carbon conversion factors and current year average exchange rates.

†† Emissions per £m of turnover.