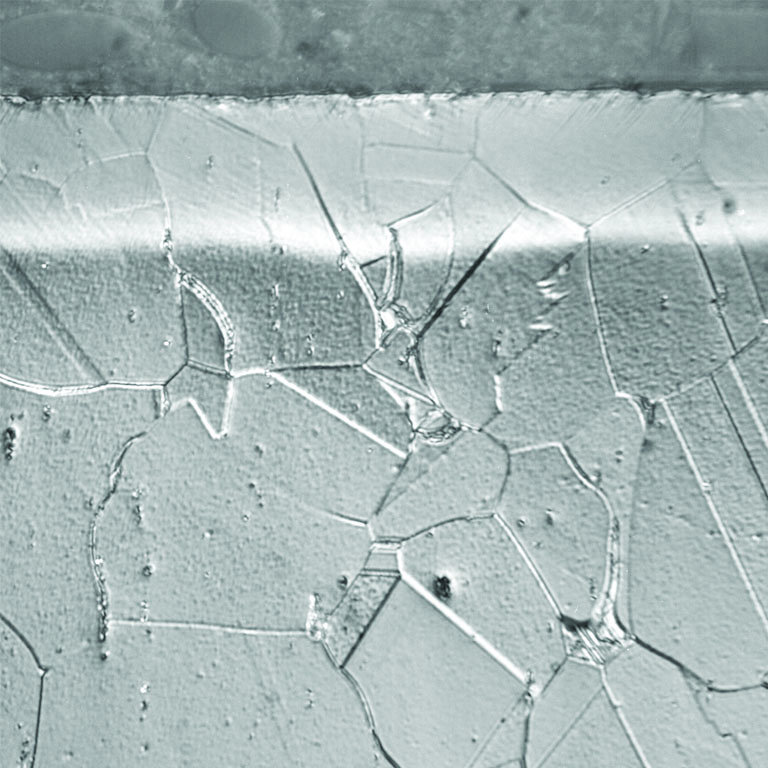

S3P is a proprietary Bodycote treatment which offers unique surface hardening solutions for stainless steel, nickel-based alloys and cobalt-chromium alloys producing increased mechanical and wear properties without adversely affecting corrosion resistance. In all S3P processes, the corrosion resistance of the base material is not altered, while exhibiting superior wear resistance, strength and ductility, as well as resistance to galling.

Bottle It

Dosing device

There are several important factors influencing the productivity of machines used in the food and beverage industry. Of the utmost importance is cleanliness, not only from microbes but also from external pollutants from machine degradation.

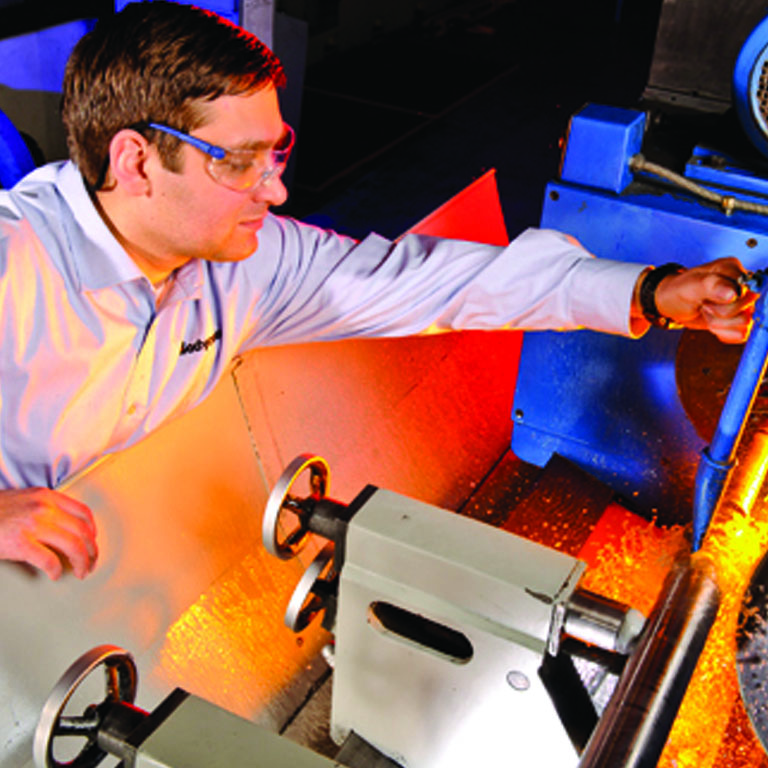

For machines which operate 24/7 with production rates of several thousands of bottles per minute, equipment must perform faultlessly and be able to withstand aggressive wear and cleaning chemicals – Bodycote's Specialty Stainless Steel Processes (S3P) provide the ultimate protection.

The device begins its journeyas steel billet. Quality and purityof the steel is critical – it mustbe free from inclusions to generate a defect-free surface.

The device is machined to tight tolerances for shape and surface perfection to ensure no leaks in the equipment.

The device is vacuum annealed to eliminate machining stressesand to impart corrosionresistant properties.

The part is polished to a mirror finish to eliminate any remaining surface defects.

Bodycote's S3P processing is applied to ensure the material can withstand the harsh conditions of high speed production, wear from food and drink, and attack from cleaning chemicals.

End application – food and beverage production.