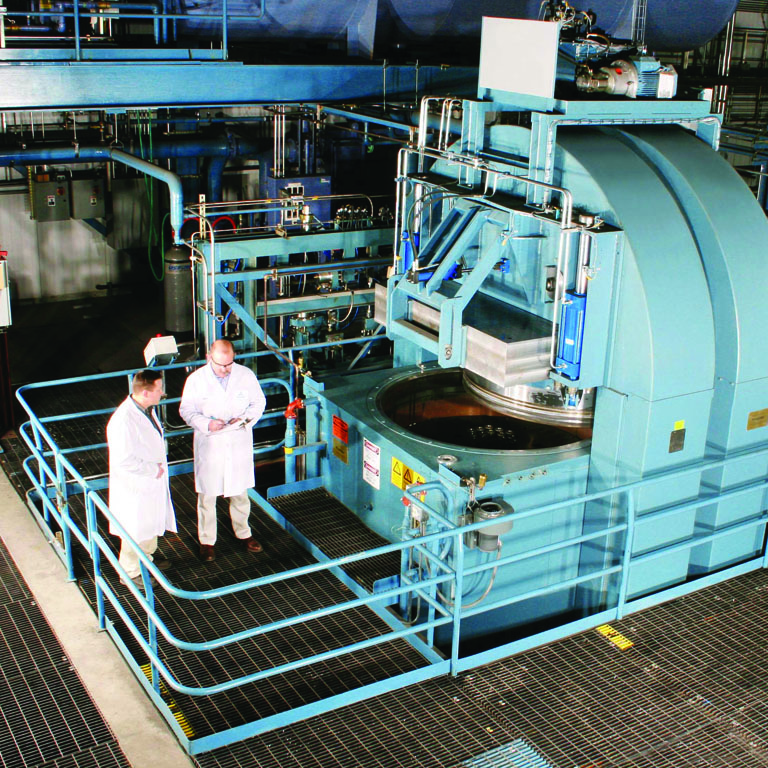

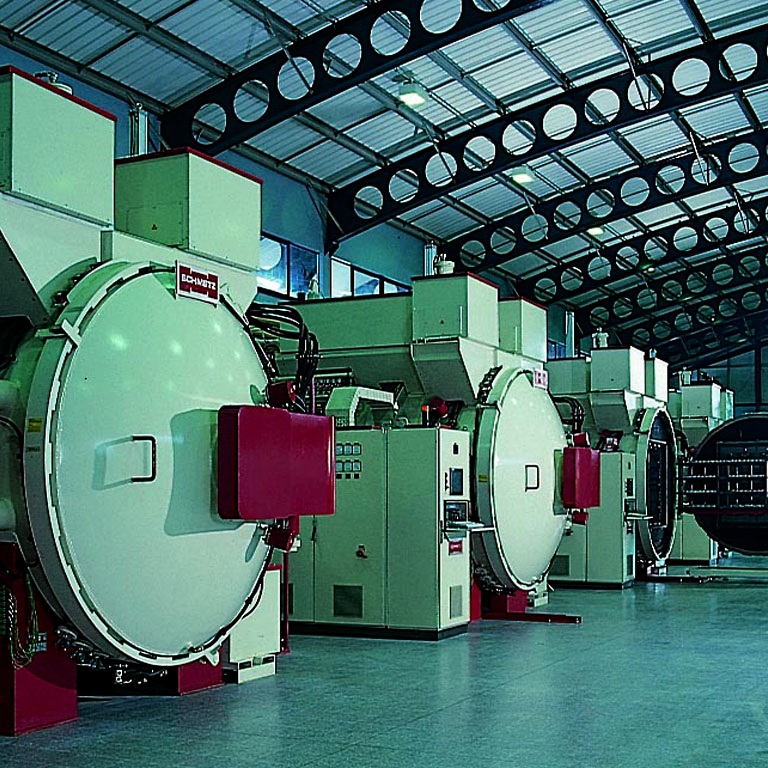

Hot Isostatic Pressing (HIP) combines very high temperature and pressure to eliminate porosity in castings and consolidate encapsulated powders to give fully dense materials. Dissimilar materials can be bonded together to manufacture unique, value-added components. With the largest operational capacity in the Western world, and a wide variety of sizes of equipment, Bodycote is able to accommodate large volumes of small product as economically as large individual components.

Inner strength

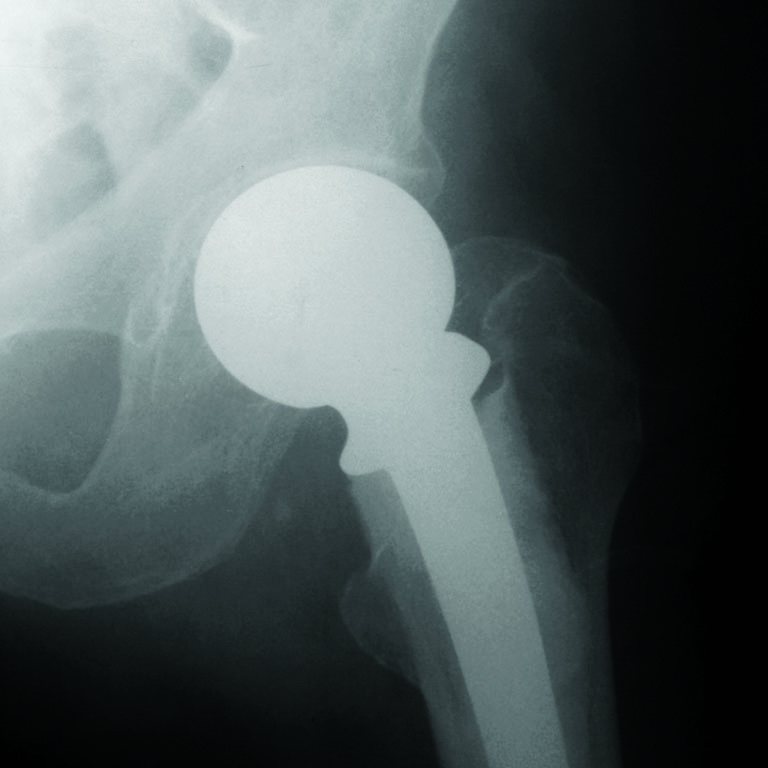

The stress on a hip or knee joint when a person jumps off a chair is equal to around 100 tonnes per square inch. Our bones, effectively composites, absorb such stresses regularly and effectively for much of our lifetime. When joints fail, they are often replaced with metal alloy implants. These implants must be incredibly strong, biocompatible, and able to last the lifetime of the patient. A combination of heat treatment, hot isostatic pressing and coating makes this possible.

Cobalt chromium alloy billets are investment cast to form implant shape.

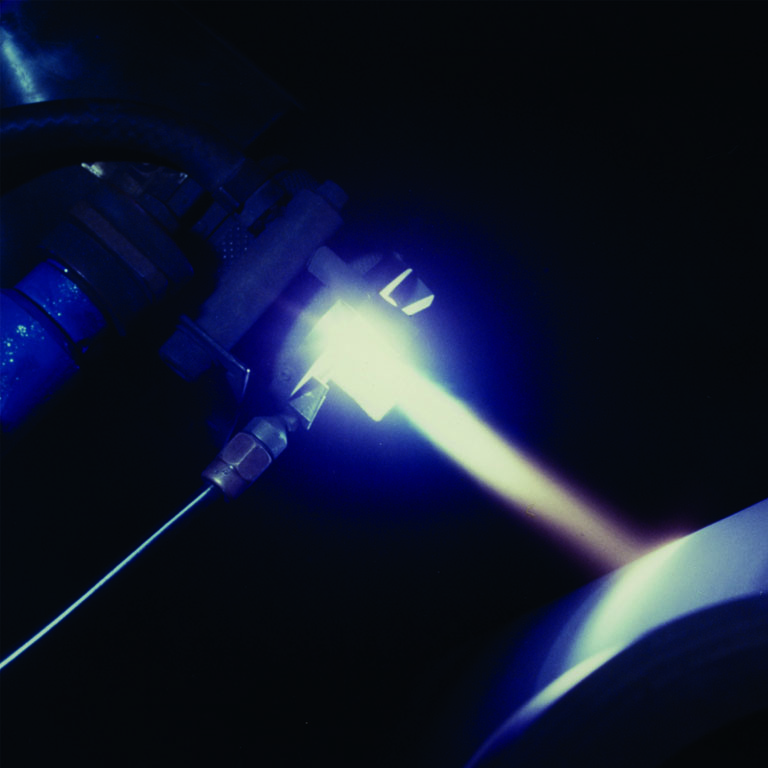

The castings are thermally sprayed with a biomedical coating to allow a bond to form between the implant and body tissue, promoting bone growth.

The implants are then HIPed to eliminate porosity, improve fatigue life and enhance the bonding ofthe biocompatible coating.

Solution and ageingheat treatment is used tostrengthen the implant.

End application – joint replacement.