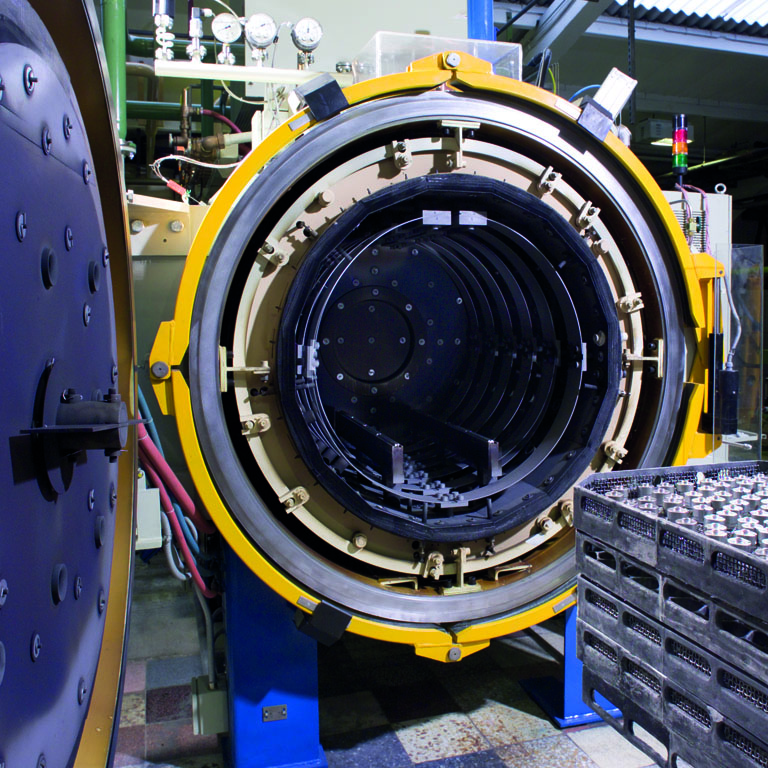

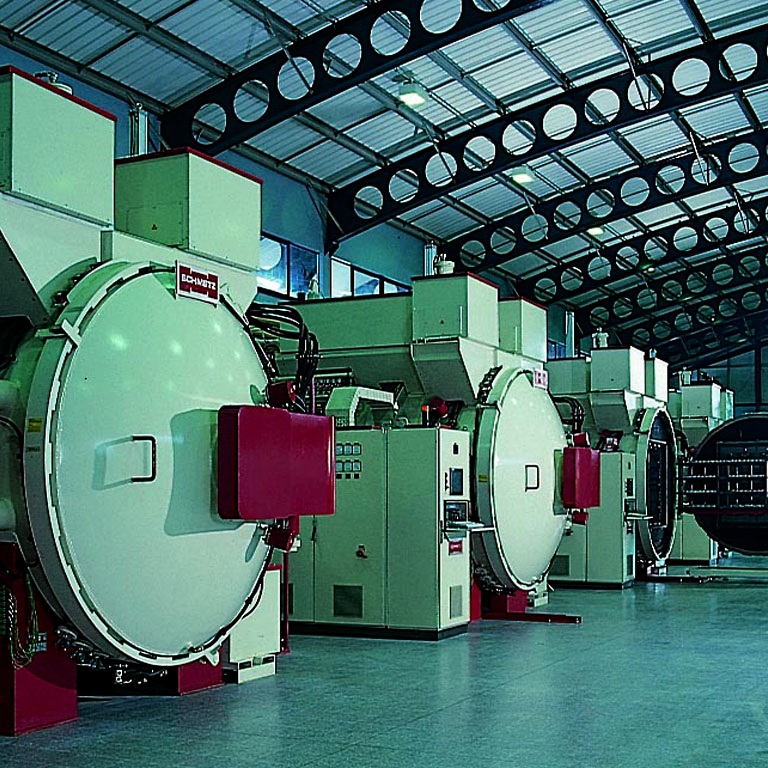

LPC is a case hardening process carried out in a vacuum furnace using hydrocarbon gases at very low pressure and elevated temperatures to obtain a hardened surface layer and a tough core. This 'clean' treatment is used to increase the wear resistance and fatigue life of components.

In Gear

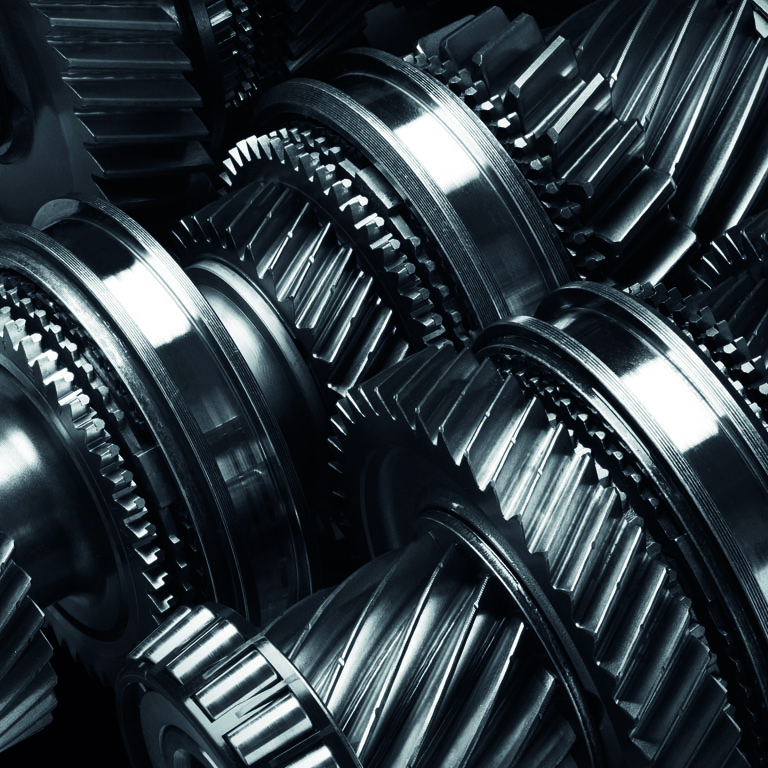

Pinion gear

A pinion gear is a critical automotive component used in virtually all transmission units. During use, a vehicle places heavy demand on its transmission, requiring a fast and reliable response to the drive controls.

The gears require high strength and wear resistance in order to withstand the stresses applied to each gear during use. Bodycote's heat treatment processes, in particular Low Pressure Carburising (LPC), enable modern transmissions to deliver high performance and seamless response, even reducing noise during gear changes.

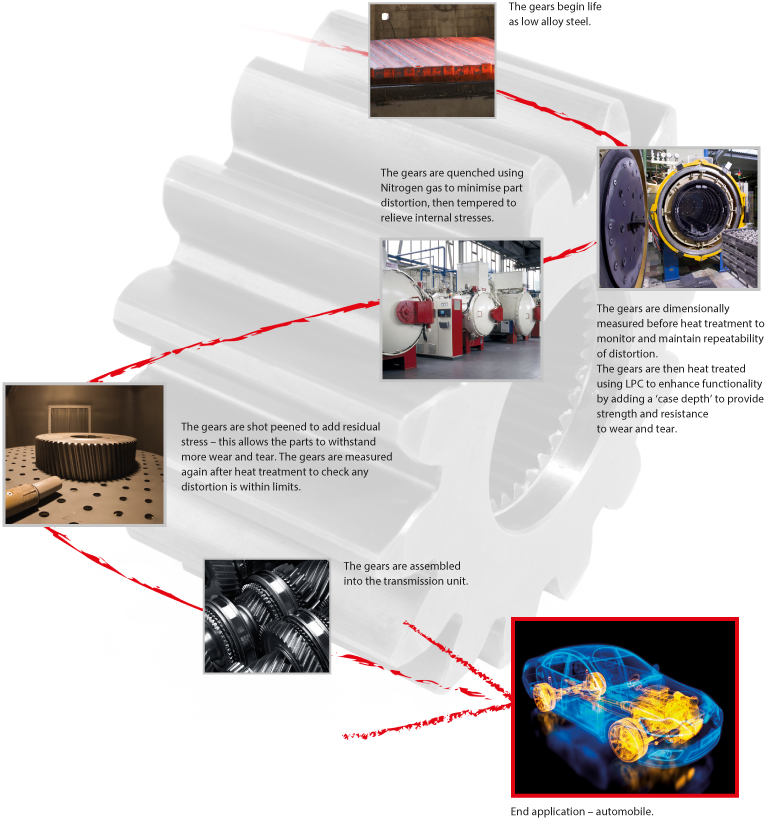

The gears begin lifeas low alloy steel.

The gears are dimensionally measured before heat treatment to monitor and maintain repeatability of distortion. The gears are then heat treated using LPC to enhance functionality by adding a 'case depth' to provide strength and resistance to wear and tear.

The gears are quenched using Nitrogen gas to minimise part distortion, then tempered to relieve internal stresses.

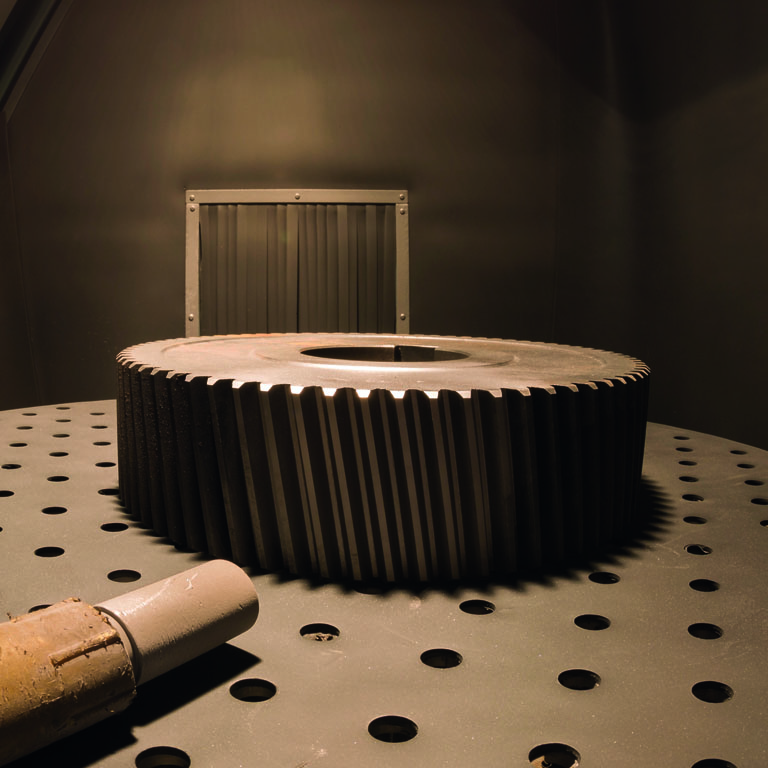

The gears are shot peened to add residual stress – this allows the parts to withstand more wear and tear. The gears are measured again after heat treatment to check any distortion is within limits.

The gears are assembledinto the transmission unit.

End application – automobile.